All-Electric and Hybrid Electric/Hydraulic Tube Bending Machines Ideal for High-Volume Operations

Unison Tube LLC, Danville, VA, will present an all-electric Breeze Twin Head tube bending machine and one of the company's all-new Synergy hybrid, multi-stack tube benders at FABTECH this year. Unison will also use the show to launch the most advanced version ever of its Opt2Sim tube bending simulation software, with several free software licenses up for grabs.

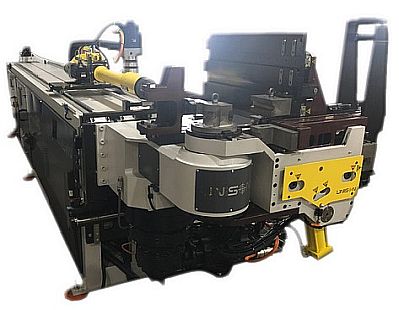

Unison All-Electric Twin Head Machine

Equipped with Unison's recently upgraded Unibend control -- an operating system offering speed enhancements of up to 25% -- all-electric Unison Twin Head 1 ½" (maximum tube diameter) machines will precision bend two ends of a tube simultaneously.

This capability makes them well suited to the high-speed manufacture of symmetrical tubular shapes typically found in automotive, agricultural and furniture applications.

New Unison Synergy Hybrid Machine

Unison's new Synergy machines combine electric and hydraulic operation with exceptional levels of control. Developed for organizations that aspire to Unison quality but carry out repetitive tube bending tasks, Synergy models provide a highly accessible entry point into the Unison range.

Available in 2" (50 mm) and 3" (80 mm) versions, Synergy machines feature a servo-driven bend arm, carriage, plane of bend and carriage side shift, with a hydraulically controlled mandrel, pressure die and clamping system. This is a combination that Unison believes make its Synergy range perfect for high volume, repetitive tube manipulation operations.

New Opt2Sim Tube Manipulation Software

In the latest iteration of Opt2Sim, Unison makes it easier than ever to import and extract tube data and includes software versions that take simulating the bending process, creating batch files and scanning tube coordinates to the next level.

VIDEO: Pipe bending simulation software -- Opt2Sim v2

Opt2Sim provides users with a complete end-to-end solution, from taking 3D STEP files to bending tube within a single software suite. Delegates visiting Unison's FABTECH booth will have the chance to win one of several Opt2Sim software licenses.

"We are delighted to be returning to FABTECH with such inspiring tube bending technologies," comments Unison Tube's Vice President, Stuart Singleton. "As industry returns to pre-pandemic levels, our aim is to help as many manufacturers and subcontractors as possible accelerate their efficiency, ingenuity and productivity. We are particularly excited to be unveiling our latest Opt2Sim software, as this really will revolutionize tube bending simulation for organizations of all sizes."

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::